What Is First-In First-Out (FIFO) in Beverage Manufacturing

A simple, proven principle that keeps beverage supply chains moving right

When you’re dealing with products that are consumed, time is everything. In the beverage industry, shelf life, taste consistency, and freshness are not just expectations; they’re non-negotiables. That’s where FIFO comes in.

FIFO, short for First-In First-Out, is a system-wide approach that ensures the products that come in first are the ones that go out first. Simple as it sounds, this principle plays a big role in reducing waste, improving quality, and keeping operations predictable, especially at the scale HCCB operates at.

Understanding FIFO: The Core Idea

At its most basic, FIFO is a stock rotation principle. It means that the oldest stock (the first items that come into the system) should be the first to be moved out or sold.

For perishable or consumable goods like juices, sparkling drinks, dairy beverages, and water, FIFO ensures that:

- Products don’t sit idle and expire in storage.

- Stock closest to expiry is moved out first.

- Quality stays consistent from factory to consumer.

This simple rule helps prevent both understocking (from missed expiries) and overstocking (from accumulating unsold product).

Importance of FIFO in the Beverage Industry

Beverages aren’t like furniture or electronics. They have expiry dates, preferred shelf lives, and specific storage conditions. Here's why FIFO is essential for beverage manufacturers and distributors:

1. Minimises Waste

Using older stock first prevents spoilage or expiry-based losses. For high-volume categories, even a small percentage of wastage can result in high cost and product loss.

2. Protects Product Quality

Older stock sitting too long in warehouses or trucks can compromise taste and freshness, especially in dairy and juice products. FIFO ensures the consumer always gets a fresh experience.

3. Improves Inventory Accuracy

With FIFO, tracking inventory age becomes easier. It helps warehouse teams maintain tighter control and ensures more accurate stock valuation in financial reporting.

4. Supports Regulatory and Food Safety Compliance

Using stock in order of arrival supports traceability. In the event of any recall or investigation, it’s easier to track batches and take quick action.

Where FIFO Applies in the Supply Chain

FIFO is a principle that works across multiple points in the supply chain, not just warehouses.

1. Raw Material Management

Ingredients like fruit pulp, sugar, CO₂, and flavours also have shelf lives. Applying FIFO at the raw material level helps maintain consistency in product formulation.

2. Production Floor

Once raw materials are issued, FIFO is followed while batching and blending to ensure uniformity across product lines and reduce hold-ups.

3. Finished Goods Warehouses

This is where FIFO is most commonly implemented. Pallets are arranged so that the oldest are picked first. Clear labelling, rack planning, and warehouse management systems (WMS) support this flow.

4. Distribution and Logistics

Dispatch planning ensures that the oldest inventory is routed to distributors first. At the truck-loading stage, staff are trained to follow FIFO to the last detail.

5. Retail and Trade

Even downstream, guidance is given to retailers to stock shelves with the newer products behind and older ones in front, enabling sell-through in FIFO order.

What FIFO Looks Like in Practice

A FIFO system may vary from site to site, but here are some real-world components:

1. Barcode and Batch Tracking

Every batch is scanned into the system with a date and a unique identifier. This allows systems to automatically suggest the oldest stock for dispatch.

2. Dedicated FIFO Racking

Storage areas are designed so that newer stock is physically placed behind older inventory, making it easier to pick the right pallet.

3. Clear Visual Labelling

Date codes and batch numbers are clearly displayed on cartons, shrink wraps, and pallet tags. This helps floor teams make fast and correct decisions.

4. System Alerts and Cut-Offs

Warehouse management software sends alerts when certain stock crosses shelf-life thresholds. This allows teams to prioritise usage or take preventive actions.

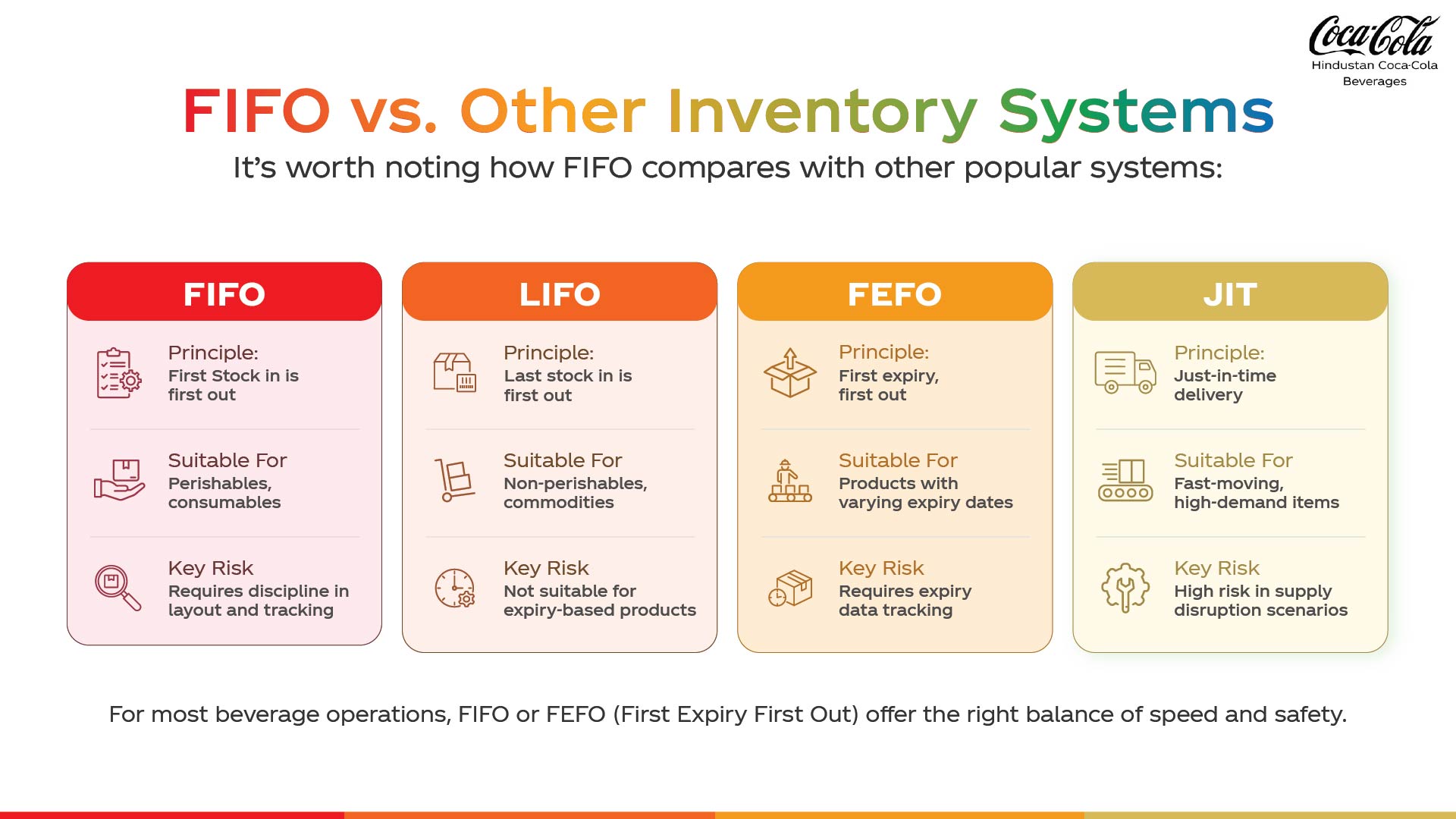

FIFO vs. Other Inventory Systems

Challenges in Implementing FIFO

Even though the concept is simple, implementing FIFO can get complex without the right systems and behaviours in place.

Common challenges include:

- Mixing of SKUs with similar packaging

- Storing products without proper date alignment

- Manual errors in picking or stacking

- Rush orders that skip FIFO checks

- Lack of training at the dispatch and delivery points

These are best addressed through:

- Routine FIFO audits

- Employee training refreshers

- Warehouse layout optimisation

- Integrated warehouse software tools

The Role of Technology in Supporting FIFO

Technology strengthens FIFO discipline across all stages.

- Warehouse Management Systems (WMS): These track stock age, suggest pick lists, and block out-of-sequence dispatch.

- Route Planning Tools: Help plan deliveries using oldest batches based on destination and shelf-life.

- IoT Sensors: Provide data on storage conditions, alerting teams if products may degrade faster.

- Mobile Apps for Field Staff: Ensure last-mile FIFO checks and inventory age reporting at distributor points.

Training for FIFO Compliance

People are at the heart of FIFO. It only works if every team member follows the process, especially on the ground.

Training programmes should include:

- FIFO basics and why it matters

- How to read and sort batches

- Correct stacking and picking

- Handling exceptions and flagging issues

Many beverage companies use video walkthroughs, gamified learning modules, and refreshers before peak seasons to ensure everyone stays aligned.

Benefits of FIFO Beyond Warehousing

Beyond the warehouse, FIFO contributes to:

- Retailer Satisfaction: Distributors receive stock with longer shelf-life, reducing their risk of returns.

- Stronger Brand Trust: Fewer cases of expired or poor-quality products reaching shelves.

- Efficient Promotions: Promotional stock is moved first, aligning with launch dates and campaigns.

- Financial Clarity: Stock valuation remains accurate for reporting, helping better demand and budget planning.

FIFO and Sustainability

FIFO indirectly supports sustainability by:

- Reducing spoilage-related waste

- Preventing unnecessary rework or reprocessing

- Lowering the environmental cost of discarding expired stock

The fewer products that go to waste, the lighter the environmental footprint of operations becomes.

Why FIFO Is Relevant in the Beverage Industry

In fast-moving industries like beverages, where freshness and trust go hand in hand, the simple rule of FIFO continues to deliver consistent results. It’s not just about clearing stock, it’s about safeguarding quality, protecting timelines, and operating responsibly.

Whether you’re managing a single warehouse or coordinating across a national network, FIFO is one of those operational anchors that keeps things running smoothly.

Because in this business, the right product at the right time isn’t a bonus. It’s the baseline.

Comments